Ducting Express were contacted by one of the UK’s largest manufacturers of speciality chemicals to review the existing wood waste extraction system within their joinery workshop. The customer also expressed an interest in a new flexible extraction arm to replace a damaged flexible arm they had in welding pen within the workshop.

Following the initial enquiry our knowledgeable woodwork extraction design engineer visited the customers site to take a look at the current extraction in place and discuss the options to remove wood waste and weld fumes within the separate areas of their factory.

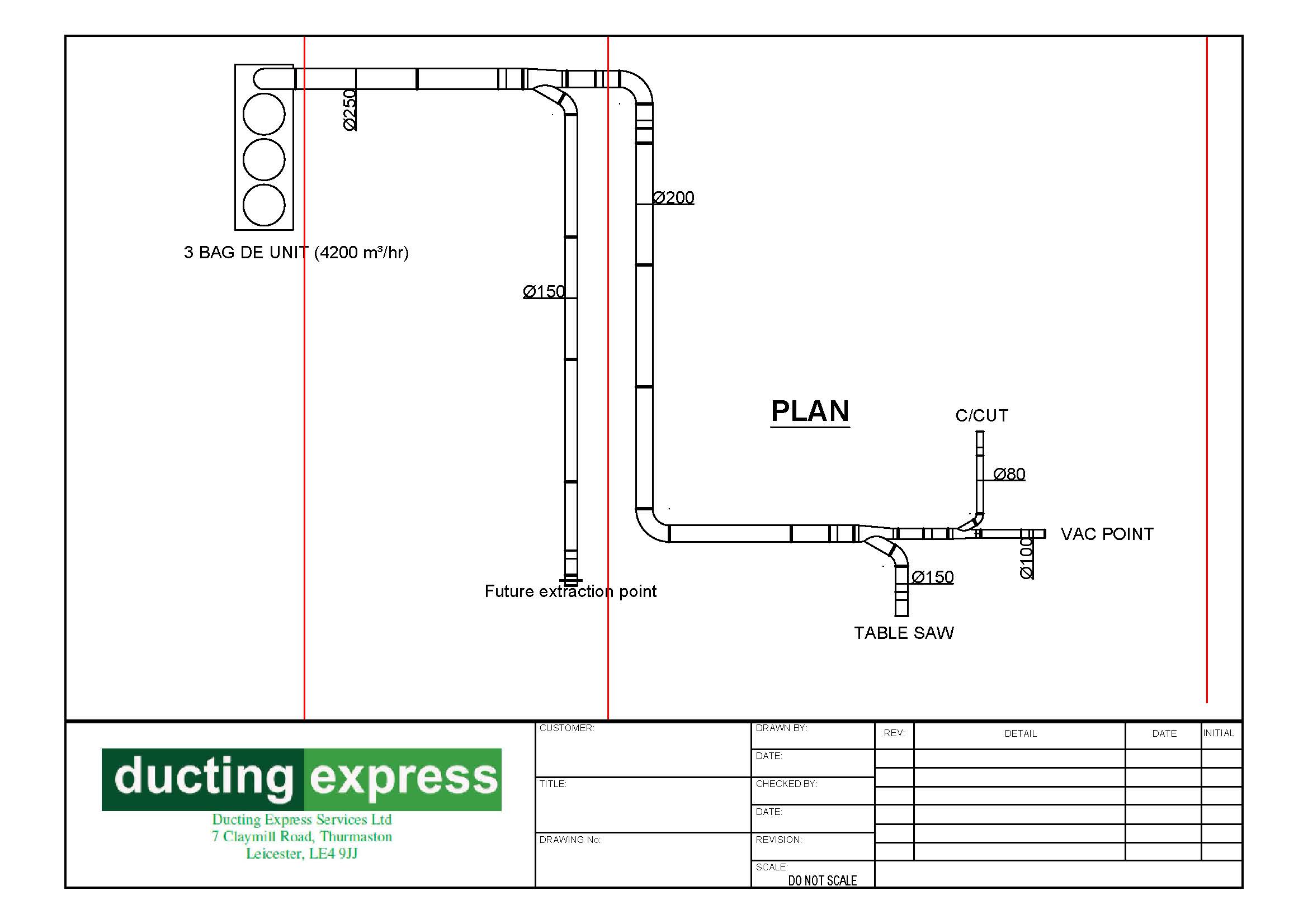

Working closely with the customer we proposed to supply and fit a new wood waste extraction filter unit and new ductwork to extract from a table saw, cross cut saw, and a future connection in the adjoining room. A further floor vacuum extract point would also be installed into the system to enable safe and easy housekeeping.

The proposed extraction unit DE 2500 can handle a volume of 4200 m3hr and would be weather proofed to enable the filter to be sited externally. The waste is collected in three 500mm diameter heavy duty waste collection plastic bags.

All connecting ductwork would be Nordfab Quick Fit ducting and would connect the wood waste extractor to the customers various wood working machines.

Installation of Kemper weld fume extraction arm

We also provided the customer with a proposal to supply and install a new Kemper 4m flexible extraction arm to replace the existing damaged flexible arm. The new arm would connect to the inlet of an existing extraction fan. The existing outlet ducting would also be modified to comply with COSHH legislation and will terminate with a Swedish cowl above the upstairs building.

The customer made the decision to have the Kemper 4m flexible extraction arm installed first. This installation took place on a single day by two of our experienced fitters. On completion of installation our LEV engineer visited site to commission the flexible arm and issue an LEV report.

Installation of Wood Waste Extraction System

Following completion of the weld fume extraction installation the customer decided to proceed with the wood dust extraction system. The proposed design was agreed with the customer and our design engineer and, subsequently a suitable date for the installation to take place was agreed.

The installation took place over a four day period. All ductwork was fitted using heavy duty brackets and fixings.

We supplied an electrical control panel that the customer had their own electrician carry out the electrical installation.

The system and ductwork was designed to handle a maximum of 2 machines at any one time. The system is an either or system, To maintain sufficient velocities in the main ducting. Nordfab manually operated dampers were installed at each machine outlets.

On completion of installation another LEV COSHH test was undertaken to update the customers existing reports in accordance with HSG258 recommendations.

Looking for a similar solution in to wood dust problems in your workshop? Contact the team at Ducting Express on 01455 616 444 today. Our team of experienced wood waste extraction engineers can advise you of the best solution.

For more information on the health effects of inhaling wood dust visit the HSE website here.