Ducting Express were contacted by a building materials company to get advice and a quotation for a Dust Extraction System to suit a new brick profiling machine which was to be installed. The design would need to ensure that sufficient extraction was provided to safely remove the brick dust produced to comply with occupational exposure limits.

Following the initial enquiry our experienced design engineer arranged to visit the customer’s site to measure the area and collect information about the machine and its operators’ process.

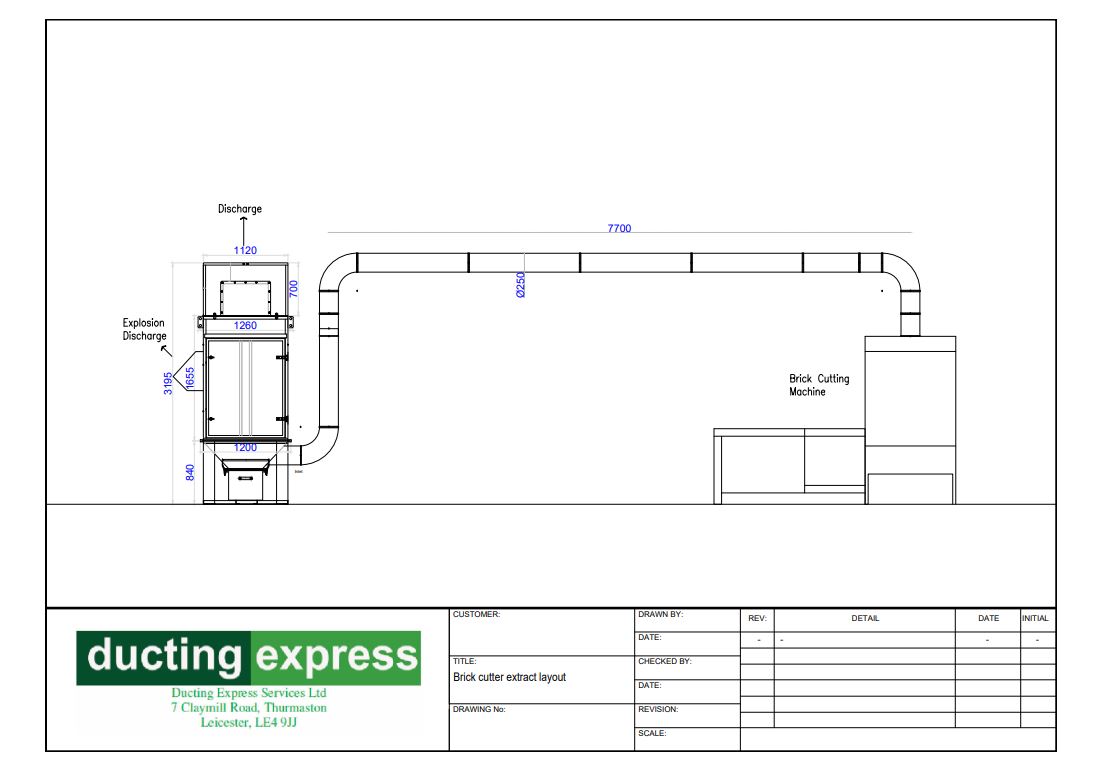

Working closely with the customer, who provided the extraction airflow rates of the brick profiling machine, we then proposed the supply & install of a suitable dust extraction unit which would be connected to the new brick cutting machine using Nordfab clipped ducting.

The extraction system was designed to filter and collect the hazardous substance for safe disposal. Due to the abrasive nature of the dust we advised the use of Nordfab clipped ducting so that any warn parts can be easily replaced. We were also able to design the new dust extraction filter unit to be the same RAL colour as the customer’s machinery.

Our team of skilled installation engineers visited site to install the system over a period of two days. On completion of installation the extraction system was then tested by our commission engineer who issued a full COSHH LEV certification for the system.

The dust extraction system successfully extracts the brick dust produced at source and ensures a safe working environment for the customer and their employees.

If you are looking for a similar solution or have questions about how we could help with extraction in your workshop today please do not not hesitate to give us a call. Our team of knowledgeable design engineers would be happy to help you find the perfect solution.