Ducting Express Services Ltd were contacted by one of the UK's largest commercial printing companies to resolve a problem they had with dust from their new Heidelberg Printing Press. The dust was not only causing health & safety issues but also creating a problem with production.

Following the initial enquiry one of our design engineers attended site to discuss the issues, firstly about the health & safety and then the production problems the dust was causing.

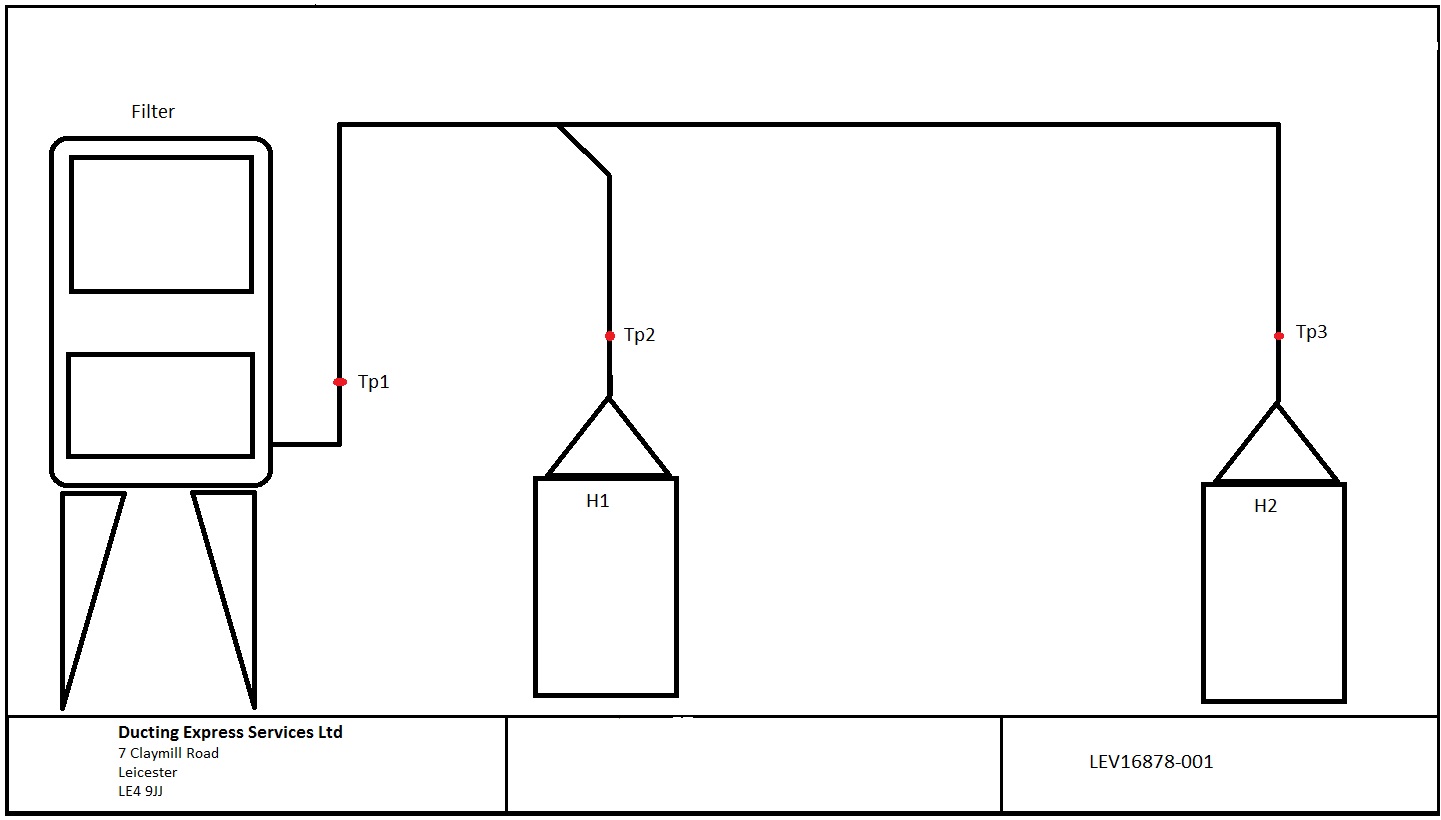

We then designed a simple system comprising of an ATEX reverse jet dust extraction filter connecting to two Heidelberg printing presses.

The dust is removed from the printing press and extracted through galvanised spiral ducting into an externally sited DE DCH3 X 16 reverse jet cartridge dust extraction filter. The dust is then simply collected in a plastic bag and can be easily disposed of.

DE DCH3 X 16 reverse jet cartridge dust extraction filter

The DES pulse jet cleaning, free standing cartridge unit has been designed for use in dust control applications where a compact, high efficient dust control unit is required to operate continuously over long periods of time.

The DES pulse jet unit utilises automatic constant pneumatic cleaning of the cartridges which allows the unit to be operational for long lengths of time without the need to stop the system for clean down of the filter media.

The cartridges filters used are of a single open ended type therefore there is only one seal required on the open ended dust end. Due to the high levels of filtration that can be achieved by the use of cartridges this allows for a more compact unit design that requires less floor space, but can still achieve high filtration levels.

Cleaning of the cartridge elements is carried out by means of compressed air injection from the clean air side, this reverses the normal flow of air through the cartridge element, with the passage of air dislodging the dust held on the cartridge which drops into the collection bin. Cleaning of the elements takes place on a continuous basis with a run-on-timer fitted as standard.

The Dust Extraction System Installation

The installation took place over 4 days with the commisioning and LEV testing being carried out on the 5th day. On completion the LEV test report was issued to the customer for there H&S records

By having the new system installed the customer can now have peace of mind that they were compliant and that their employees are safe.

If you have any similar issues with dust control in your workshop or would like to see how Ducting Express can help with dust and fume extraction contact our team on 01455 616 444 today.