Spray Booth Filter Media

What Type of Spray Booth Filters Do Professionals Use and Why?

In order to keep a safe working environment and meet the government regulations, spray booth filters are mandatory. Their job is to catch any pollutants from overspray and keep them within the fibres. This also protects the airflow system and helps extend the lifetime of the equipment. For different types of booths, different techniques for installing the spray booth filters apply.

For cross-draft booths, the filters are laid within a grid on the side walls. The air flows from one side to the other, in correlation with your spraying angle. Those filters come in pads, but you can buy a roll of spray booth filter and cut it in pieces that suit your grids dimensions.

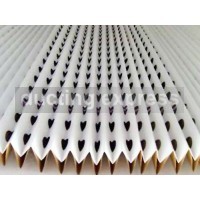

The wall you are spraying towards to will have spray booth extractor filters that are kept in place by the grid. This grid prevents the filters from being sucked in the air extraction system. In most cases, a two-layer filtration system is implemented. The first line of protection would be a fibreglass filter, followed by a secondary filter at the back. In most cases, paper pleated filters are used for that second line of filtration. The reason behind this is to prevent any overspray from ending up in the air extraction ducts and minimise the time spent during annual cleaning and maintenance.

In downdraft spray booths the airflow is from the ceiling to the ground. Once again, you have spray booth filters on both sides. The top side is providing fresh air into the booth and the filters are making sure no excessive particles end up on your paint. The bottom side is extracting the airflow. Air is being sucked in and any excessive overspray is caught in the filters. Spray booth filters in rolls are preferred for downdraft booths, especially for the bottom side. When it is time to dispose of the filters it is easier to just roll them back and take them out.

Different applications need different types of spray booth filters. Some can take a bigger load, some are just cheaper and easier to find. It all depends on what you are planning to do in your workspace. Let’s talk about the different types of spray booth filters on the market. What are the pros and cons of each type and when you might want to opt for any given variant?

Spray booths are largely used for automobile painting. Because of the size of the “element”, you are painting and the number of details, you need a precise flow of air that is well filtered. A pollutant with a size above ten microns can ruin your paint, although you won’t be able to see it right away.

Paint Booth Filters and Exhaust

For downdraft booths, different types of paint booth filters are used. A common thing between them is that they have a MERV rating of ten and above. Such rating ensures you get above 99% of efficiency, plus it catches particulates as big as 10 microns. Those paint booth filters are installed on the “intake” side of a downdraft booth. The intake side is the one feeding fresh air inside. A single layer of glass fibre filter media should take care of the intake. You also have the option of synthetic air filters, but their structure is not as dense as that of glass fibre filters.

Now that we have covered the intake it is time to explain a bit more about the exhaust side of a paint booth. This is the point from which air is released back in the environment, and that is the reason we need to pay attention to it. As we have mentioned in the previous paragraph, this exhaust air must meet government restrictions. It needs to be as pure as possible. There should be no signs of lacquers, paints or debris. The paint booth filters that we will instal on the exhaust side of the booth need to prevent those potentially harmful substances to escape outside, but also keep them off the airflow inside the booth. Airborne aerosols could be inhaled by workers in the booth or even absorbed through the skin. The paint booth filters used on the exhaust end are made out of multilayered polyester and/or fibreglass. This allows them to catch bigger loads of overspray without allowing drips. Options that have the so-called “pockets” can take even bigger loads. This multilayered design allows for the paint booth filters to endure longer periods of extensive use. That means they don’t need frequent changes, cutting costs as an end result.