Wood Waste Extraction Systems play an important role in ensuring the health & safety of your employees. However, here at Ducting Express, we very often see common problems with poorly designed and maintained woodworking dust extractors that could mean that the system won’t work at its best and could potentially cause health & safety risks.

Our team of experienced dust & waste control engineers often get called to site to investigate existing wood waste extraction systems. Below is a list of some of the most common problems we see:

- Flexible ducting split & leaking

- Incorrect flexible ducting used

- Main duct work incorrectly sized

- Filter media leaking or blinded

- Waste collection bags or bins leaking

- The use of 90 degree T-pieces

- Incorrect fan rotation

- Explosion panels on dust extraction filters obstructed/placed incorrectly

- Poor housekeeping

- Lack of training

- “What is LEV Testing? I didn’t know this was a legal requirement”

Lots of these problems have quick and easy solutions and are often general common sense. They usually fall under two categories; wood waste extraction systems maintenance & design. We have categorised these for you below along with our advice. Please note that you should always seek advise from a specialist company prior to carrying out any modifications to your Wood Waste Extraction System.

Wood Waste Extraction Systems Maintenance

Most fires in wood waste extraction systems are caused by either human error or lack of maintenance (sharpening chisels on a belt sander that is connected to your dust extractor is a recipe for disaster (air / fuel / ignition source). The main maintenance issues are below:

Poor housekeeping

Poor housekeeping will reflect poorly on your business as any visiting potential customers will see this as a reflection of your work. Poor housekeeping generally occurs due to the fact that there is not a designated person responsible for this. Assigning this to one person makes it not only the employer’s responsibility but also the responsibility of the person whose role it is to keep the area clean and safe. We would also advise where possible to install a floor vacuum kit adjacent to your waste extraction filter to enable easy housekeeping.

Flexible ducting split & leaking

Using tape to repair flexible ducting is a very short-term fix. Flexible ducting should be classed as a consumable and ideally you should carry a small amount of stock and replace the split flexible ducting as soon as you can. Ducting Express stock Polyurethane (PU) flexible ducting and can dispatch this from our warehouse as quickly as the same day.

Filter media leaking or blinded

Leaking filter media will allow dust to pass through your dust extraction filter and discharge to either the working environment or to atmosphere. This is a health and safety issue and an environmental issue and the consequences could lead to your business being forced to close down. If your filter media starts to leak, you will need to turn off your extraction system immediately & replace your filter media. It is an environmental offence to discharge dust to the atmosphere. Regular maintenance could prevent this from happening. To keep spare filter media in stock is cheaper that having to stop production while awaiting new filter media to arrive. Ducting Express stock various different types of dust extraction filter media to suit your wood waste extraction system.

Waste collection bags or bins leaking

This one falls under the same bracket as poor housekeeping; the emptying of wood waste extraction bags and bins, in most circumstances, is done by any member of staff that has the time to do so. This can become a problem as there may be a lack of training for all staff. If this is made one person’s responsibility the employer can make sure that this employee receives the correct training.

LEV Testing

There is a legal requirement to have your extraction system tested to ensure it is fit for purpose every 14 months for wood waste extraction systems. Ignorance is not an excuse for not having this done. Contact us today if your system is due an LEV Test.

Woodworking Waste Extraction Design

Incorrect type of flexible ducting used

The type of flexible ducting to use will depend on the dust/waste being extracted. This should be considered during the design phase of your wood waste extraction system.

Main duct work incorrectly sized

Poorly designed extraction duct work will affect the performance of your wood waste extraction system & could result in the system failing mandatory LEV Testing. Always seek professional advice from a specialist company when designing a system to suit your wood working workshop’s needs.

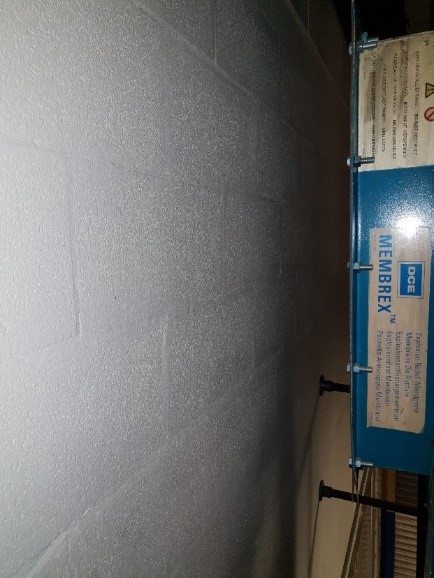

Explosion panel placement

Explosion panels are placed on dust extraction filters for a reason. They should never be placed against a wall or next to other obstructing machinery. More importantly, an employee should never be working adjacent to an explosion panel. These should always be vented into a safe area.

The use of 90 degree T-pieces

We would always advise the use of 45 degree T-pieces as these cause significantly less resistance and aid in the performance of your extraction system.

Incorrect extraction fan rotation

Some people think that if the main extraction fan was running backwards it would blow air the other way, however, if a fan rotation is incorrect it will still suck but around 55% less.

Capacity

A surprisingly large number of people think that once they have an extraction system, they can simply add additional machines to this system, in most cases this may not be possible due to the capability of the extraction system and ductwork design.

LEV Testing

A common belief is that if you have an up to date LEV inspection certificate for your extraction system and then modify the system, your old LEV inspection certificate will still cover this as it’s within the expiry date. This is not the case, any modifications made to a LEV systems design will require a new LEV inspection.

These are just some of the common problems we see with Wood Waste Extraction Systems. If you require any advice or are looking to find a suitable wood dust extraction system for your workplace please contact us today.